Leaky Kitchen Kettles Hidden Costs

Leaky commercial kitchen kettles menace kitchen managers and food prep-technicians all across the globe on a daily basis. Not only is there a safety concern with potentially hot and slippery contents covering floor traffic areas, there are also sanitation and financial concerns. Spilled kettle contents require clean up and can get into kitchen areas that are difficult to sanitize. This leads to increased time to clean and extra dollars sanitize. Leaky kettle valves also waste product, change the mix ingredient ratios, change batch temperatures and ultimately lower food quality.

Current old technology kettle valves don't help this situation. The customary valves used today utilize a rubber plug that seals the kettle port. It becomes disfigured due to wear, heat, and chemical degradation resulting in leaks. Overtightening can also push the valve shaft through the rubber plug resulting in failure. The handle mount on this design also has exterior threads. When a handle gets hit the threaded nub typically breaks off requiring either a stop-gap weld (stainless steal) to try and remount the handle or a total stem valve replacement. In either case this costs time and money.

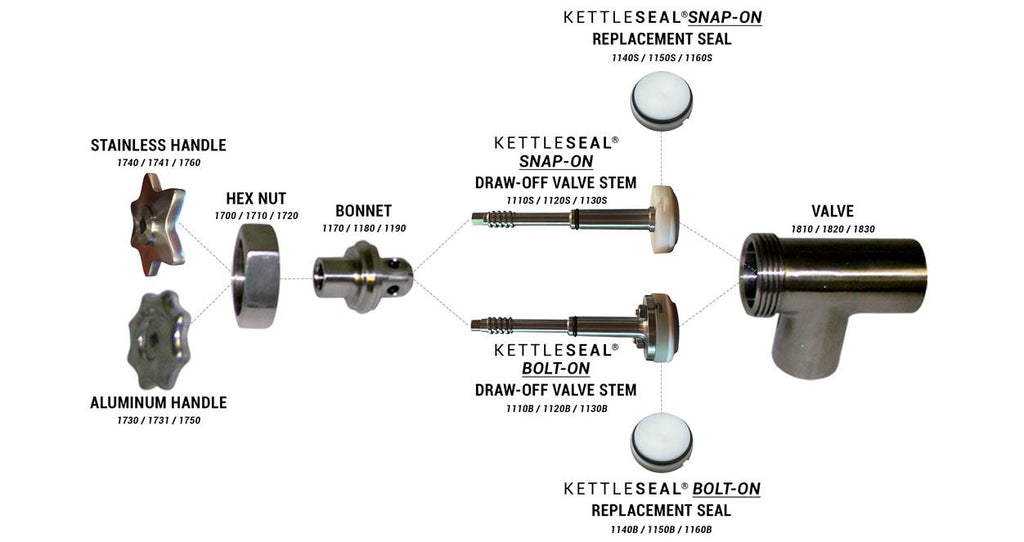

There's an easy fix however called KettleSeal. This new patented valve system increases the lifespan of your stem valves considerably. In fact the "kettle seal" is made from food grade nylon and it backed by a 3 year limited warranty. Should the nylon seal wear out over time, all you do is replace the nylon seal, not the whole stem valve. Another interesting feature is KettleSeal uses internal handle threads. Should a handle get hit, it's more likely the handle will break versus the stem valve. This saves time, money, improves safety and food quality.

KettleSeal products work with all major 1 1/2", 2" and 3" kettle and braising pan stem valve set-ups. They also come in snap on or bolt on seal configurations.